NASA Tests Technology Offering Potential Fuel Savings for Commercial Aviation

4 min read

Preparations for Next Moonwalk Simulations Underway (and Underwater)

NASA researchers successfully completed a high-speed taxi test of a scale model of a design that could make future aircraft more efficient by improving how air flows across a wing’s surface, saving fuel and money.

On Jan. 12, the Crossflow Attenuated Natural Laminar Flow (CATNLF) test article reached speeds of approximately 144 mph, marking its first major milestone. The 3-foot-tall scale model looks like a fin mounted under the belly of one of the agency’s research F-15B testbed jets. However, it’s a scale model of a wing, mounted vertically instead of horizontally. The setup allows NASA to flight-test the wing design using an existing aircraft.

The CATNLF concept aims to increase a phenomenon known as laminar flow and reduce wind resistance, also known as drag.

A NASA computational study conducted between 2014 and 2017 estimated that applying a CATNLF wing design to a large, long-range aircraft like the Boeing 777 could achieve annual fuel savings of up to 10%. Although quantifying the exact savings this technology could achieve is difficult, the study indicates it could approach millions of dollars per aircraft each year.

“Even small improvements in efficiency can add up to significant reductions in fuel burn and emissions for commercial airlines,” said Mike Frederick, principal investigator for CATNLF at NASA’s Armstrong Flight Research Center in Edwards, California.

Reducing drag is key to improving efficiency. During flight, a thin cover of air known as the boundary layer forms very near an aircraft’s surface. In this area, most aircraft experience increasing friction, also known as turbulent flow, where air abruptly changes direction. These abrupt changes increase drag and fuel consumption. CATNLF increases laminar flow, or the smooth motion of air, within the boundary layer. The result is more efficient aerodynamics, reduced friction, and less fuel burn.

The CATNLF testing falls under NASA’s Flight Demonstrations and Capabilities project, a part of the agency’s Integrated Aviation Systems Program under the Aeronautics Research Mission Directorate. The concept of was first developed by NASA’s Advanced Air Transport Technology project, and in 2019, NASA Armstrong researchers developed the initial shape and parameters of the model. The design was later refined for efficiency at NASA’s Langley Research Center in Hampton, Virginia.

“Laminar flow technology has been studied and used on airplanes to reduce drag for many decades now, but laminar flow has historically been limited in application,” said Michelle Banchy, Langley principal investigator for CATNLF.

This limitation is due to crossflow, an aerodynamic phenomenon on angled surfaces that can prematurely end laminar flow. While large, swept wings like those found on most commercial aircraft provide aerodynamic efficiencies, crossflow tendencies remain.

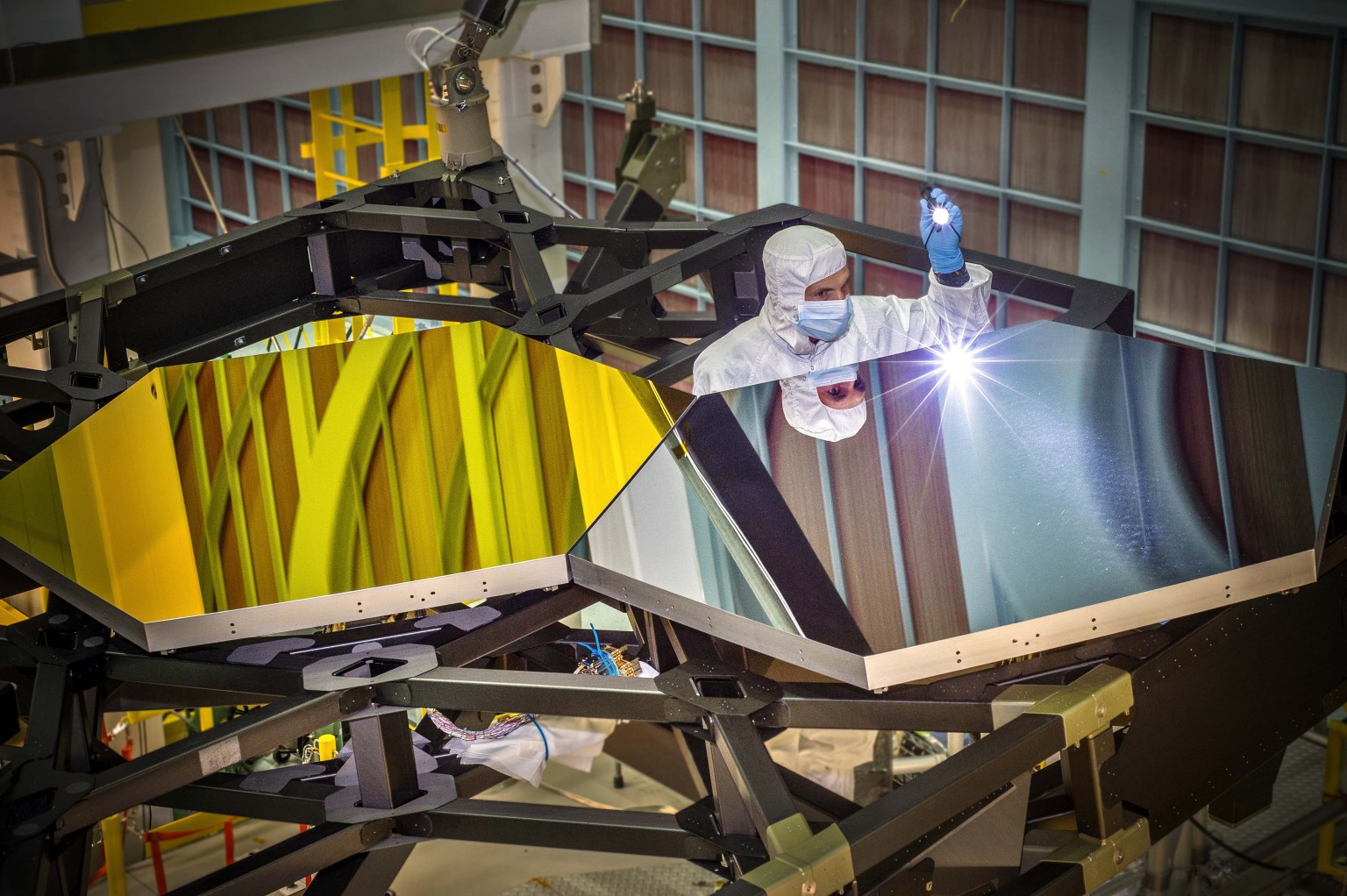

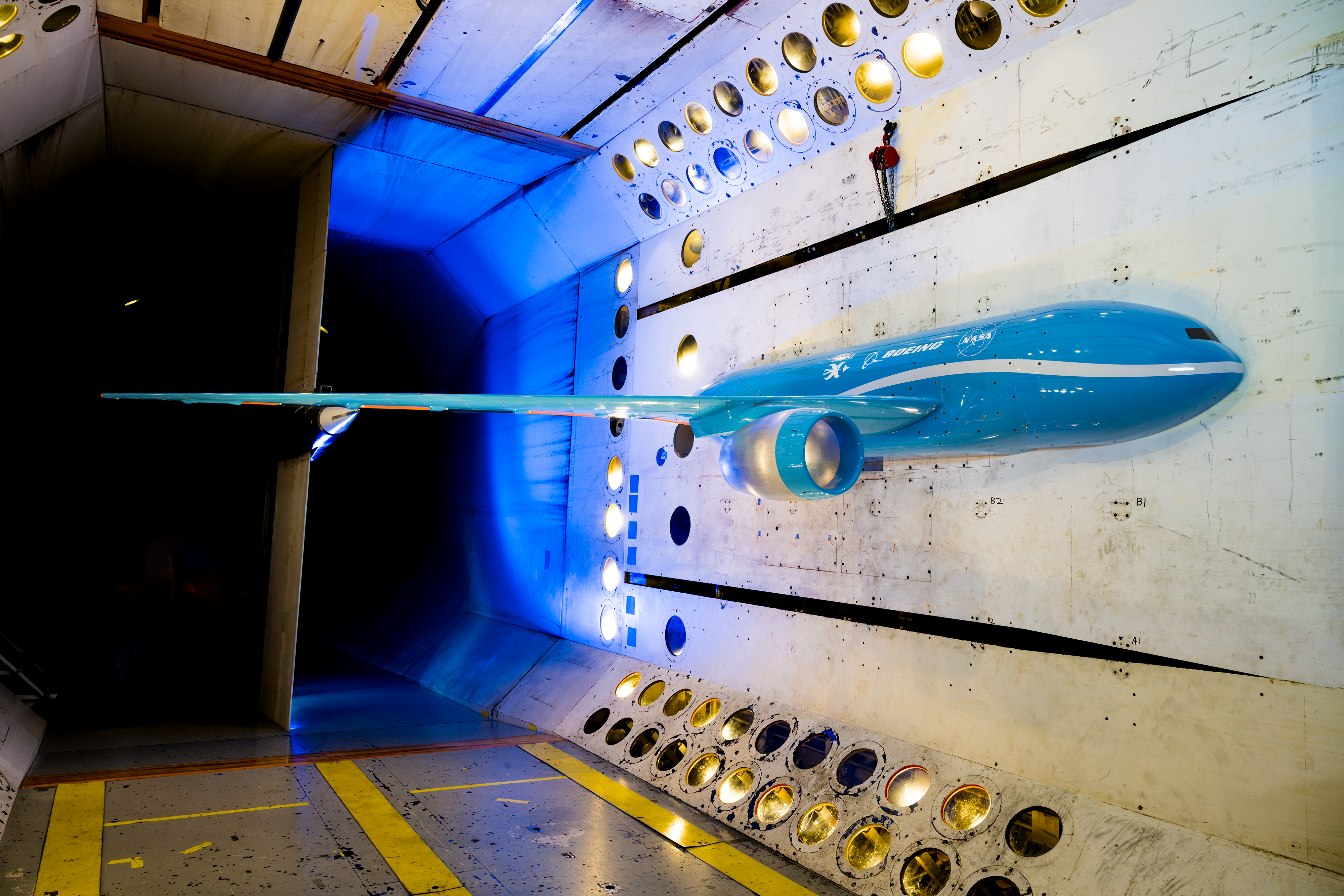

In a 2018 wind tunnel test at Langley, researchers confirmed that the CATNLF design successfully achieved prolonged laminar flow.

“After the positive results in the wind tunnel test, NASA saw enough promise in the technology to progress to flight testing,” Banchy said. “Flight testing allows us to increase the size of the model and fly in air that has less turbulence than a wind tunnel environment, which are great things for studying laminar flow.”

NASA Armstrong’s F-15B testbed aircraft provides the necessary flight environment for laminar flow testing, Banchy said. The aircraft enables researchers to address fundamental questions about the technology while keeping costs lower than alternatives, such as replacing a test aircraft’s wing with a full-scale CATNLF model or building a dedicated demonstrator aircraft.

CATNLF currently focuses on commercial aviation, which has steadily increased over the past 20 years, with passenger numbers expected to double in the next 20, according to the International Civil Aviation Organization. Commercial passenger aircraft fly at subsonic speeds, or slower than the speed of sound.

“Most of us fly subsonic, so that’s where this technology would have the greatest impact right now,” Frederick said. NASA’s previous computational studies also confirmed that technology like CATNLF could be adapted for supersonic application.

In the coming weeks, CATNLF is expected to begin its first flight, kicking off a series of test flights designed to evaluate the design’s performance and capabilities in flight.

Looking ahead, NASA’s work on CATNLF could lay the groundwork for more efficient commercial air travel and might one day extend similar capabilities to supersonic flight, improving fuel efficiency at even higher speeds.

“The CATNLF flight test at NASA Armstrong will bring laminar technology one step closer to being implemented on next-generation aircraft,” Banchy said.